ZDTP-50

CHEMICAL NAME: Phosphorodithioic acid, mixed O, O-bis (2-ethylhexyl and iso-Bu) esters, zinc salts

CAS NO: 68442-22-8

EINECS:270-478-5

SPECIFICATIONS:

| 50 | Carrier | EPDM | |

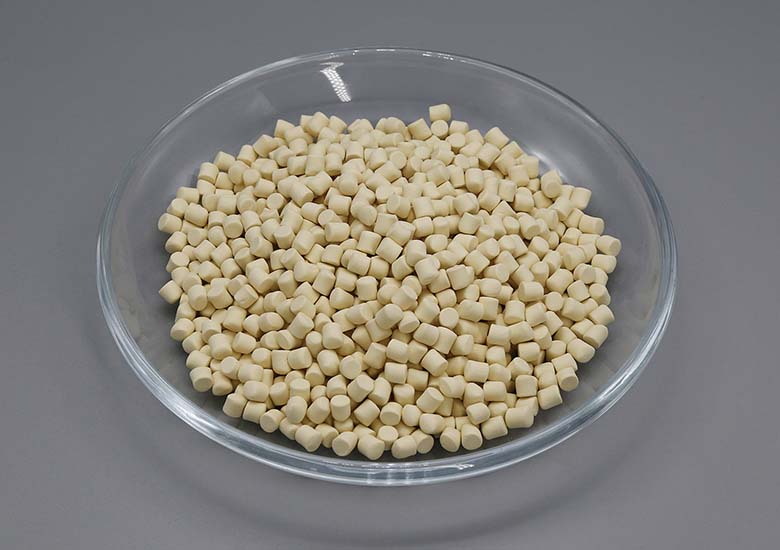

| Appearance | Milk white translucence Granules | Purity | 98% |

| Sulfur Content | 8.5 | Sulfur content | 14.5-16.9 |

| Density(g/Cm³) | 1.20 | Heating loss content | 0.5% max |

| Composition | Mixture of 50% Phosphorodithioic acid, mixed O, O-bis(2-ethylhexyl and iso-Bu) esters, zinc salts and 50% polymer and dispersing agent | ||

※Binder type can be customized. Except EPDM, others binders, such as SBR, NBR also can be available for.

PROPERTIES:

ZDTP is a special accelerator for EPDM which contains sulphur, ZnO, thiazoles and thiurams accelerant.

It can lead to high degree of cross-linking and no blooming with maximum usage dosages recommended.

ZBOP masterbatch has processing safety and storage stability.

As an ingredient of effective vulcanization system it is an accelerator for vulcanization of rubber such as NR, IR, BR, NBR, IIR, etc and its vulcanizate has excellent heat resistance.

It is an assistant accelerator with thiazoles, thiurams, sulfenamides for vulcanization of EPDM and NR.

There is no hazardous nitrosamines during curing process.

APPLICATION:

Engineering molded and extruded products such as films, tyre buffer layers, rubber fenders, seals, etc.

DOSAGE:

For NR: 2-3phr;

For SBR/NBR: 2-3phr;

For EPDM: 2-3phr.

PACKING & STORAGE:

Net weight 25kg/PE bags lined carton; Net weight 600 kg/pallet.

Shelf-life: 1 year in its original packaging .

Stored in a dry and cool place.

Compared to traditional ZBOP liquid, YLSCH-RBB® ZDTP-50GE F500 allows:

Avoidance of smelly pungent odor of ZDTP liquids due to masterbatch with slight odor, production environment improver.

Effective guarantee of activity of ZDTP due to pre-dispersed masterbatch.

Tack free products at room temperature, convenience and accuracy on ingredients.

Lower Mooney viscosity at lower temperature (50℃), higher quality of dispersion.

Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thanks to filtration.

Wider compatibility with other elastomers.