TDEC-75

CHEMICAL NAME: Tellurium diethyldithiocarbamate

MOLECULAR FORMULA: C20H40N4S8Te

MOLECULAR WEIGHT: 720.68

CAS NO: 20941-65-5

CHEMICAL STRUCTURE:

SPECIFICATIONS:

| Active Content(%) | 75 | Carrier | EPDM |

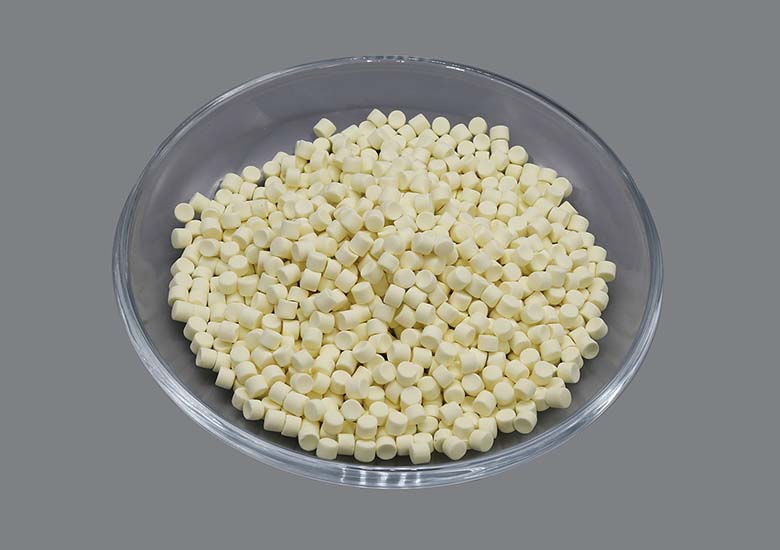

| Appearance | Orange-Yellow Granules | Initial Melting Point | 108℃ min |

| Sulfur Content | 26.0 | Purity | 98% |

| Density(g/Cm³) | 1.23 | Tellurium content | 16.5-19.0% |

| Heating loss content | 0.5% max | ||

| 63μm sieve residue | 0.5% max | ||

| Composition | Mixture of 75% Tellurium diethyldithiocarbamate and 25% polymer and dispersing agent | ||

PROPERTIES:

TDEC combined with thiazoles, thurams and dithiocarbamates accelerators can accelerate sulfuration of EPDM and IIR. A little TDEC can shorten the sulfuration time. Moreover, it is particularly suitable for high oil content soft rubber compounds such as low-hardness solid EPDM seals or spongy seals due to reduction of sulfuration rate by a great deal of softening oil.

APPLICATION:

Vehicle and building seals, vehicle hoses, steamproof & acidproof hoses, cable jacket, insulated products.

DOSAGE:

Max 0.5 phr to avoid blooming.

PACKING & STORAGE:

Net weight 25kg/PE bags lined carton; Net weight 600 kg/pallet.

Shelf-life: 1 year in its original packaging.

Stored in a dry and cool place.

Compared to traditional TDEC powders, YLSCH-RBB®TDEC-75GE F140 allows: :

Dust free products with a complete filtration up to 100µm, no skin sensitization, health guard of operators.

Effective guarantee of activity of TDEC due to pre-dispersed masterbatch.

Tack free products at room temperature, convenience and accuracy on ingredients.

Lower Mooney viscosity at lower temperature (50℃), higher quality of dispersion.

Impurity free, blocked filter free of extrusive products, scrap rate reduction and higher productivity thanks to filtration. Wider compatibility with other elastomers.