Foaming Agent ADC

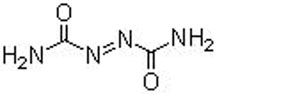

CHEMICAL NAME: Azodicarbonamide

MOLECULAR FORMULA: C2H4N4O2

MOLECULAR WEIGHT: 116.08

CAS NO: 123-77-3

CHEMICAL STRUCTURE:

SPECIFICATIONS:

| Active Content(%) | 75 | Carrier | SBR |

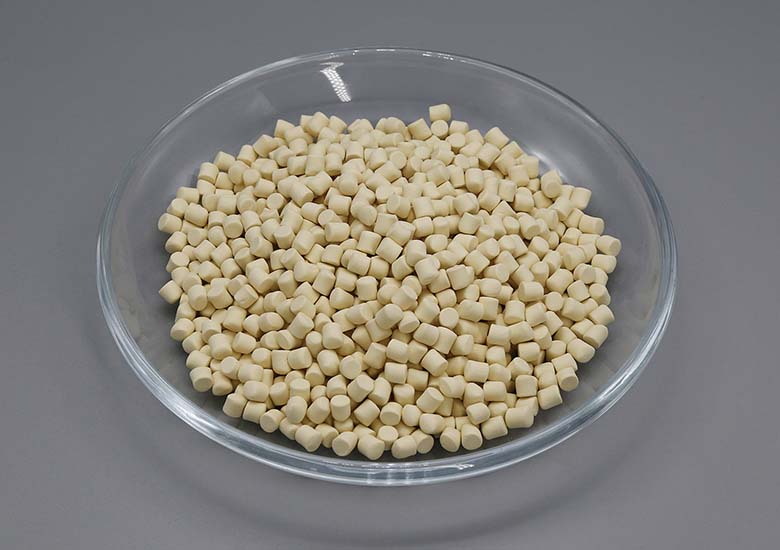

| Appearance | Yellow Granules | Melting Point | 220-225℃ min |

| Gas Evolution (ml/g) | 160 | Ash Content | 0.1% max |

| Density(g/Cm³) | 1.35 | Mean grain size | 12μm max |

| 38µm Sieve Residue | 0.1% max | ||

| Composition | Mixture of 75% Azodicarbonamide and 25% polymer and dispersing agent | ||

PROPERTIES:

ADC is a nitrogenous organic foaming agent for various rubbers such as CR, EPDM, IIR, NBR(NBR/PVC) and SBR, especially for tiny and uniform pored products. ADC powder has a relatively high foaming temperature (200-210℃), which can be effectively reduced by addition of small amount of foaming activators. It will not promote abnormal odor of foaming products.

APPLICATION:

Various foam rubber products.

USAGE:

1-10phr usually.

PACKING & STORAGE:

Net weight 25kg/Carton lined PE bag; Net 600 kg/pallet.

Shelf-life: 1 year in its original packaging on conditions of lower temperature(< 35℃) and drying(< 50% RH)

Compared to traditional ADC powders, YLSCH ADC-75 allows:

Dust free products with 6-8µm mean size grains of ADC, production environment improver.

Lower decomposition temperature and effective guarantee of activity of ADC due to pre-dispersed masterbatch and special formula.

Tack free products at room temperature, convenience and accuracy on ingredients.

Lower Mooney viscosity at lower temperature (50℃), higher quality of dispersion, homogeneous apertures of foam products.

Wider compatibility with other elastomers.

GET THE SPECIFICATION: